Your VCCA

Incubator

programme

Every year, 56% of vegetables and 61% of fruits are wasted after harvest globally, from the initial harvesting, grading, packaging, and transportation from field to storage and distribution to the consumers. A large portion of the losses in the post-harvest phase of the fresh produce value chain are caused by poor infrastructure and logistics, lack of proper cooling technology, insufficient skills, knowledge and management capacity of supply chain actors, and inadequate market linkage.

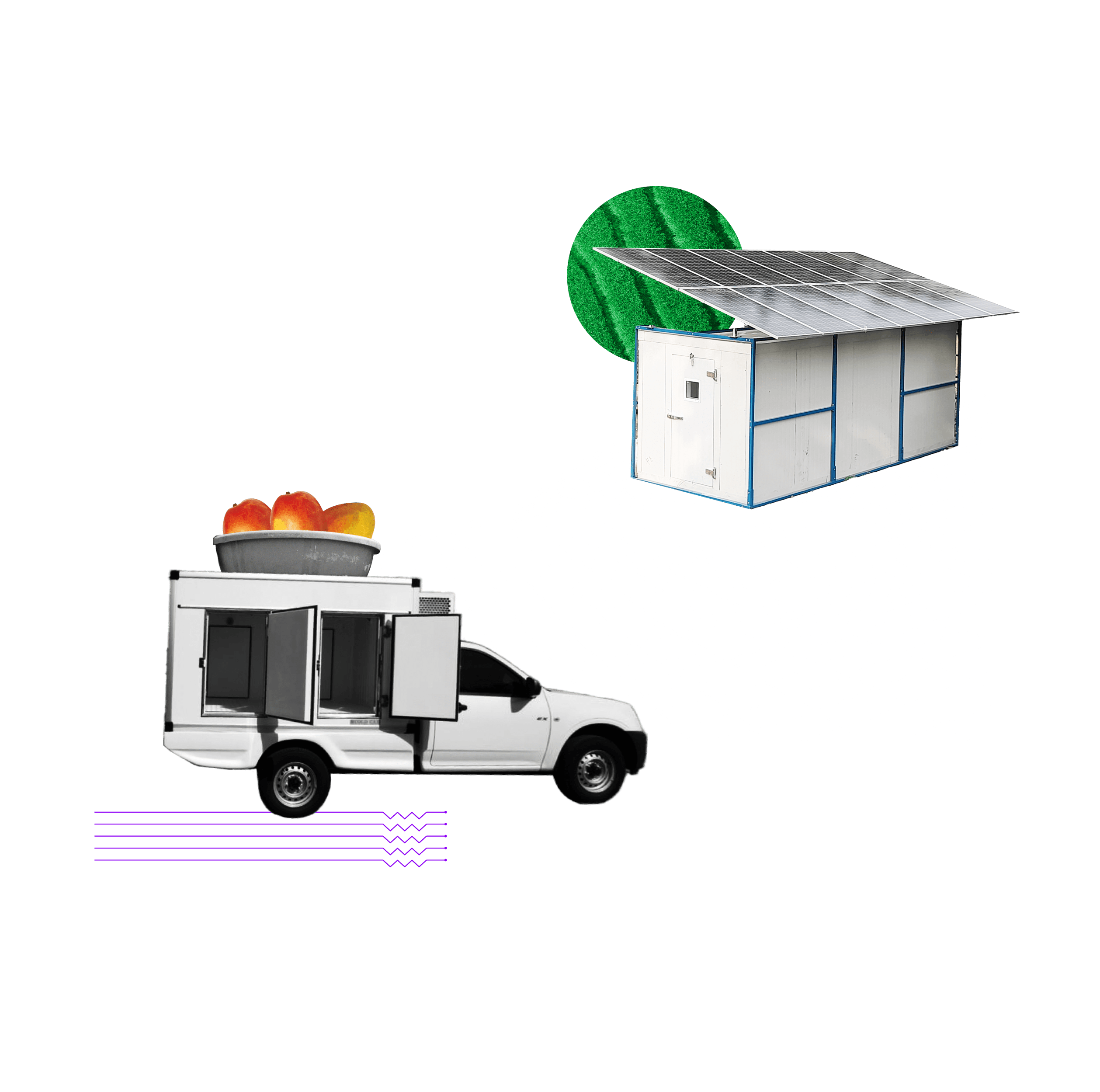

The YourVCCA Incubator programme is working with five fast-growing cooling companies journeying to make decentralised, clean cold rooms affordable and accessible to smallholder farmers in developing countries. Technology alone cannot, however, solve all the problems of food loss in post-harvest stages. Concerted effort is required to involve the farming

WHO IS THIS FOR?

The incubator is open for applications from technology providers offering highly efficient solar-powered cold storage solutions in the agricultural sector, using low-global-warming potential or natural refrigerants and thermal storage. To be eligible, the technology should focus on helping smallholders to access agricultural cold chains, thereby reducing post-harvest loss and improving livelihoods.

The call for application welcomes global, regional and local companies wishing to integrate servitisation (pay-per-use model) into their business lines,made easily implementable by the Your VCCA project through digitalisation and the use of data-science.

WHY SUBMIT AN IDEA?

The 5 selected companies will receive free technical assistance from BASE and Empa to integrate their technological solution with the servitisation business model and to digitalise the operations with the open-source and data-driven mobile application, Coldtivate, that we have created.

Selected companies will receive support to test and deploy the solution, and also benefit from international exposure through case studies and public relation activities. Furthermore, incubator participants will have access to our global network.

WHAT IS

SERVITISATION?

Servitisation is a business model through which access to products is enabled on a pay-per-use basis, without transfer of ownership or responsibility for maintenance or operation. In the case of agricultural cold storage, it means smallholder farmers and petty traders can access cold storage, while only paying per crate (or per kg) per day.

Find out moreWHAT IS

COLDTIVATE

Coldtivate is an open-source mobile application that BASE and Empa have developed to digitalise the servitisation model and to provide data-driven post-harvest intelligence to smallholder farmers such as real-time data on produce expected shelf life.

Find out more

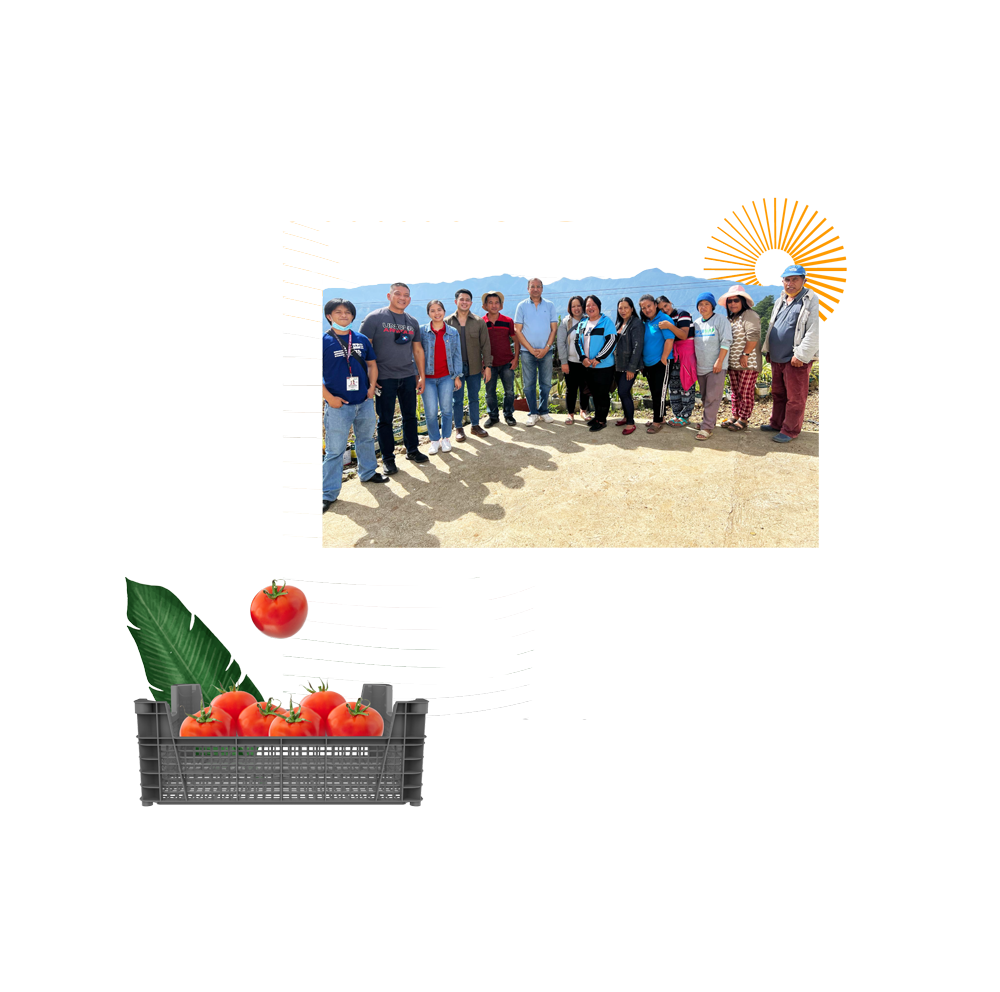

Fresh Depot, an in-house initiative of Aboitiz Group, will be the first portable cold storage network available to farmers in the Philippines.

In 2023, it will deploy a solar-powered cold storage unit of 5 metric tons at a local trading centre, Benguet Agri-Pinoy Trading Center in

La Trinidad, reaching around 10,000 farmers.

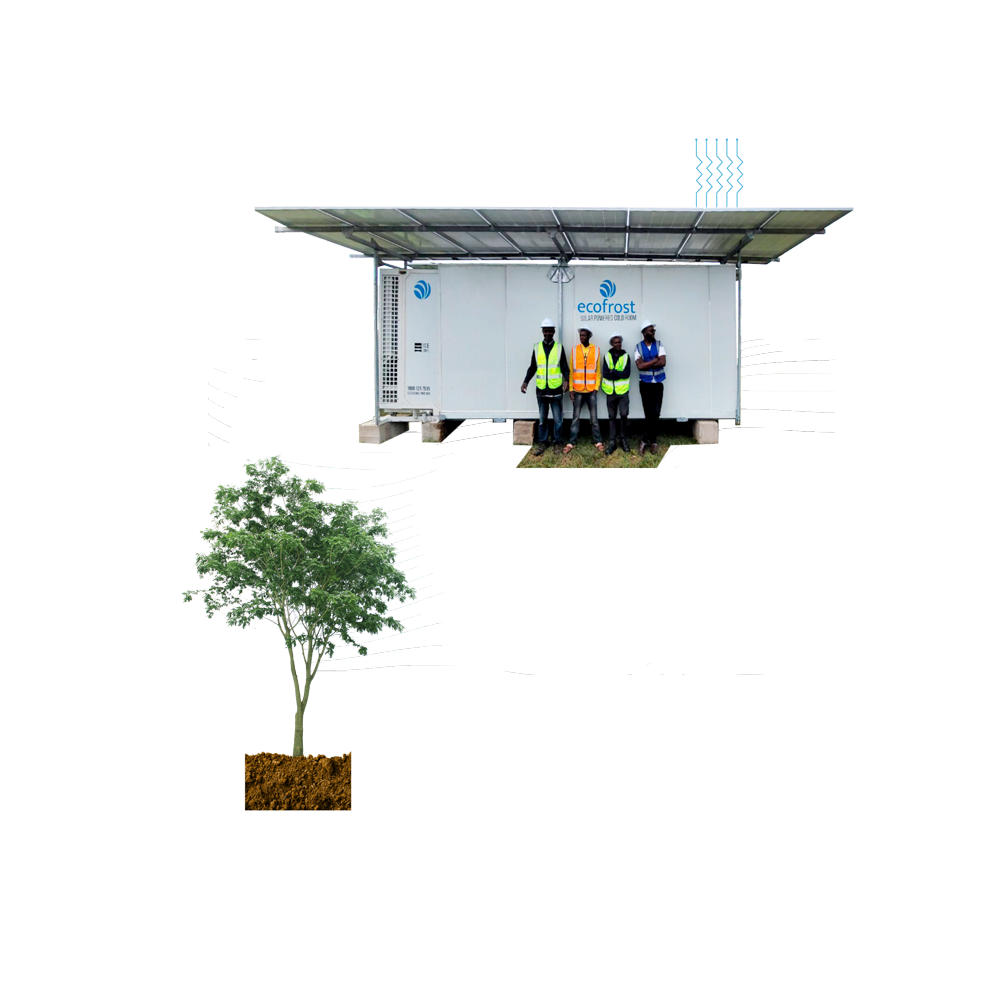

Ecozen has been enabling farm-to-fork value chains for perishables globally through cost-effective cold storage units that harness solar energy and unique thermal energy-based technology for optimum compressor usage since 2010. YourVCCA will be integrated into Ecozen’s 5-metric ton solar cold room in Isibania, Kenya, with the potential to reach 250+ farmers.

Read more Visit Ecozen

SuGree’s, in partnership with Chill Chain, has newly built a controlled-atmosphere cold room with 650 metric tons of capacity to serve as a Mother Cold Storage Room in the pilot city of Vadodara, Gujarat, India. A smaller-sized solar-power cold room, called a satellite, will be built near a fruit and vegetable market to help between 250 and 300 farmers, wholesalers, and retailers reduce food loss.

Read more Visit SuGree

Leap Energy presently has 13 sites through which it offers off-grid energy for powering agricultural services, including cold storage. The YourVCCA solution will be integrated into two rooms in Ognibo and Abuja of 20 and 10 metric tons, respectively, for digitalising inventory and remotely monitoring the shelf-life of fresh produce in storage. LeapEnergy envisions reaching 200+ cooling users through these cold rooms, including downstream vendors.

Together, Impagro Farming Solutions and Pluss Advanced Technologies are setting up a cold room of 20 metric tons to store seasonal fruits and vegetables in Khamariya Nimawar in Madhya Pradesh’s Raisen district. Using state-of-the-art technologies, such as solar-based micro rooms, thermal energy storage, and energy-efficient glycol-based cooling system using low-GWP refrigerant, their cold room aims to serve 100 to 150 farmers, with potential for expansion to villages in Gujarat and Rajasthan, India.

Read more Visit Impagro

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

The Winners

LEARNING MATERIALS

GET ACCESS TO YOUR VCCA

LEARNING MATERIALS

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Learning materials

Any questions?

Don’t hesitate to contact us at:

info@yourvcca.org